- Design Ideas

- Cities

- Trends

- Guides

- Price Calculators

- Our PortfolioNEW

- More

- Home

- Trends

- Modular Solution

- Modular Wardrobe

- Wardrobe Materials

Wardrobe Materials: A Practical Guide to Choosing the Right Cupboard Material

Most wardrobe problems don’t show up on day one. They creep in later. This happens when shelves bend, shutters lose alignment, edges swell after one bad monsoon, and termites find a soft spot nobody checked. That usually has less to do with the wardrobe design and more to do with the material hidden behind it.

In Indian homes, wardrobes work harder than we admit. They work for daily use, heavy stacks of clothes and humidity swings. Tight bedrooms where every hinge and panel matters. Choosing the right cupboard material isn’t about chasing the best option. It’s about understanding how different wardrobe materials behave once they’re installed and forgotten.

Table of Content

Understanding Wardrobe Materials vs Cupboard Materials

Wardrobe Materials List Used in Indian Homes

Best Board For Wardrobe Carcass and Structure

Best Material For Wardrobe Doors and Shutters

Best Material For Sliding Wardrobe Doors

Termite-Proof Material For Wardrobe

Best Material For Bedroom Wardrobe Based On Use Case

Modern Modular Wardrobe Materials Explained

Best Material For Walk-In Closet Design

Wardrobe Material Options by Budget Range

Wardrobe Material Specification Checklist Before Buying

Common Mistakes When Choosing Cupboard Design Materials

The Right Wardrobe Material

Understanding Wardrobe Materials vs Cupboard Materials

People use the words wardrobe, cupboard, and almirah interchangeably. That's fine. What matters is how the structure is built. A wardrobe isn't one material. It's a combination of parts. Carcass, shelves, shutters, back panel, and hardware support. Each plays a different role. When someone says best material for a wardrobe, they're often mixing up three things:

- The board is used for the main body.

- The material used for doors or shutters.

- The surface finish they can see.

Cupboard material usually refers to the board inside, not the laminate or paint on top. That internal board decides load capacity, screw strength, termite resistance, and how long the unit stays square.

This distinction becomes critical when you're comparing cupboard design options or finalising an almirah design with a carpenter. Two wardrobes can look identical and fail very differently after a few years.

Wardrobe Materials List Used in Indian Homes

When comparing wardrobe materials, you don't need ten options. Most wardrobes in India are built from a small, practical set of boards. The real difference comes from where each one is used inside a cupboard design, not just which name sounds premium.

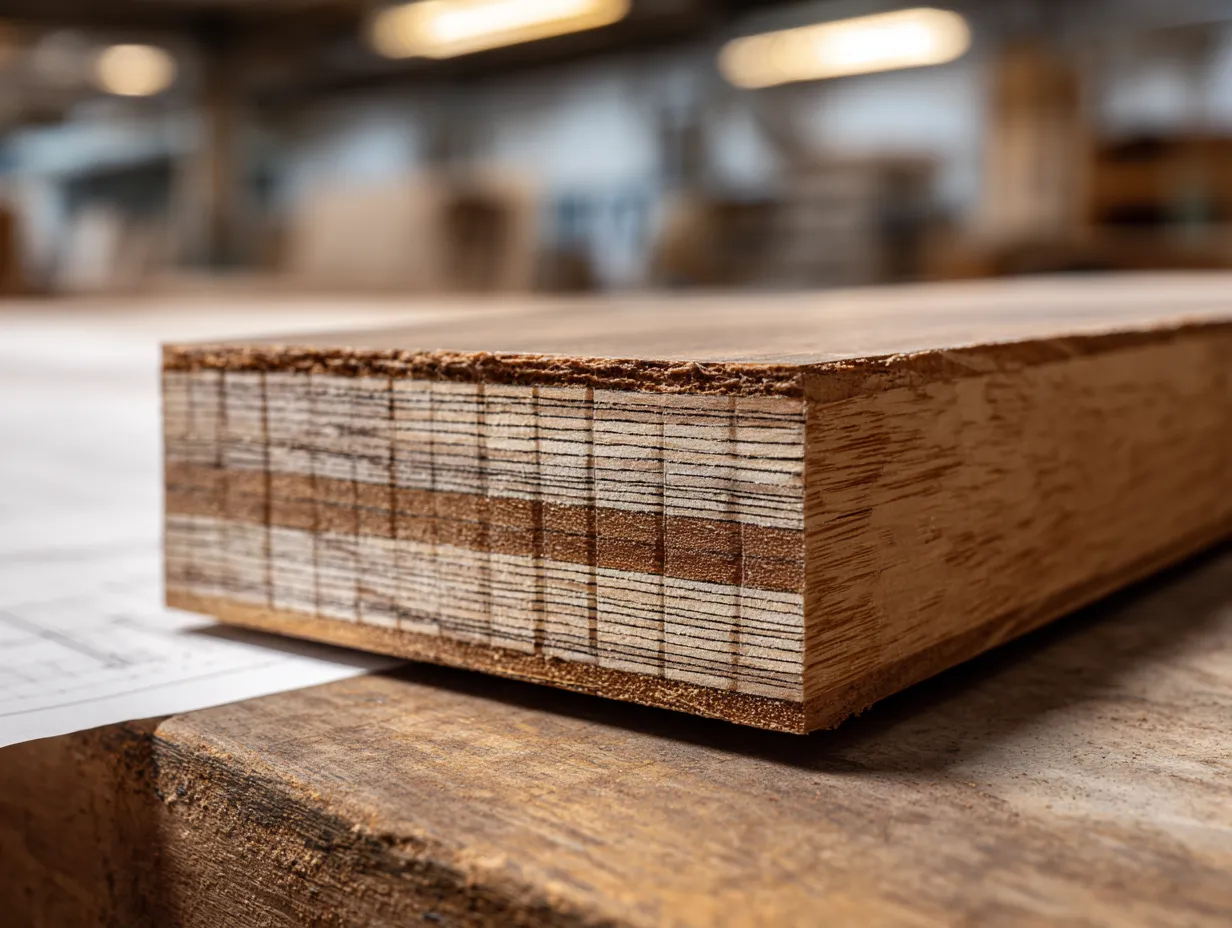

Plywood

Plywood remains the most reliable wardrobe material for structural sections because it balances strength, screw grip, and stability. It handles shelf weight without bending easily and performs well in humid bedrooms when edges are sealed. Core quality matters more than brand name, since internal gaps weaken fittings. Used properly, plywood works for carcasses, shelves, and shutters, which is why many still consider it the best material for wardrobe builds.

MDF

MDF is valued for its smooth, uniform surface, making it a common almirah material for shutters that require paint or routed designs. It delivers clean finishes but lacks structural strength compared to plywood. Heavy loads can cause gradual bending, and screws loosen faster over time. Because of this, MDF is usually limited to doors rather than internal sections where strength determines long-term performance.

HDF

HDF is denser than MDF and offers better surface strength, which is why it appears frequently in modular wardrobe materials and shutter panels. Its compact structure allows precise machine cutting and smooth finishes. Still, it isn't suited for load-bearing parts. If exposed edges absorb moisture, swelling can occur, and the board won't recover, making proper sealing essential for durability.

Particle Board

Particle board is widely used among cupboard making materials because it keeps costs low and is easy to laminate. It works for short-term or lightweight wardrobes but has limits. Screw grip is weaker, and moisture exposure can damage it quickly. Once swollen, it rarely returns to shape. For temporary setups, it's practical, but it's rarely considered the best cupboard material for long-term use.

Block Board

A block board contains wooden strips inside rather than compressed fibres, which helps it resist bending across its length. This makes it useful for tall shutters or wide panels, especially in hinged wardrobe design layouts. It's heavier than engineered boards but holds shape better over time. Carpenters often choose it selectively when shutter stability matters more than weight or cost.

Solid Wood

Solid wood is no longer common for full wardrobes, though it still appears in premium projects. Natural timber reacts to humidity and temperature changes, which can affect alignment and joints over time. Because of that movement, it's mostly used as an accent within modern wardrobe materials, such as frames or trims, rather than as the primary wardrobe raw materials for entire units.

Best Board For Wardrobe Carcass and Structure

The carcass carries the entire load of a wardrobe, so the best board for wardrobe structure isn't the one with the nicest finish but the one that stays stable under weight. Strength, screw holding, and resistance to bending matter more than surface appearance. Choosing the right baseboard determines whether a wardrobe stays aligned for years or starts shifting within months.

Plywood For Carcass

For most homes, plywood remains the safest sheet material for wardrobe frames. Its cross-layered construction distributes weight evenly and holds screws tightly, which keeps shelves firm and hinges secure. An 18 mm thickness usually handles clothing loads without sagging. Moisture-resistant grades perform reliably in bedrooms when edges are sealed. Quality matters, though. Poor core bonding or internal gaps weaken strength, so grade specification is more important than brand name.

MDF For Carcass

MDF is rarely the first choice for full carcass construction because it lacks the structural strength required for heavy storage. While it performs well in controlled factory builds, MDF panels depend heavily on support hardware to stay rigid. In site-made wardrobes, screw points tend to loosen over time, especially under repeated load. It works better as a surface or shutter board than as the main materials for the wardrobe cabinet structure.

Particle Board For Carcass

Particle board carcasses are usually selected for cost reasons rather than performance. They can work in small wardrobes with shallow shelves and light storage, but their limitations show under heavier use. Screw grip weakens gradually, and exposure to moisture can cause swelling that permanently affects the shape. Because of this, it appears mostly in budget wardrobe material options and is best chosen only when lifespan expectations are modest.

Particle board carcasses are usually selected for cost reasons rather than performance. They can work in small wardrobes with shallow shelves and light storage, but their limitations show under heavier use. Screw grip weakens gradually, and exposure to moisture can cause swelling that permanently affects the shape. Because of this, it appears mostly in budget wardrobe material options and is best chosen only when lifespan expectations are modest.

Block Board For Carcass

Block board uses internal wooden strips instead of compressed fibres, which helps it resist bending across its length. This makes it more stable than many engineered boards for vertical panels and partitions. It's heavier than MDF or particle board but holds alignment better over time. In wardrobes where panel straightness matters, block board can serve as a dependable alternative among wardrobe board types.

Best Material For Wardrobe Doors and Shutters

Shutters face the most movement in any wardrobe, so the best material for wardrobe doors depends on how they open, how heavy they are, and how well they hold fittings. Unlike carcass boards, shutter materials must balance stability with manageable weight. The wrong choice usually doesn't fail immediately but shows up later as misalignment, hinge stress, or track issues.

Plywood For Hinged Shutters

Plywood is one of the most dependable options for shutters in hinged wardrobe design because it grips screws firmly and resists bending across height. Tall shutters stay straighter, and hinges remain secure even after years of daily use. It also supports laminates, veneers, and acrylic finishes well. The only concern is weight, since large plywood shutters can feel heavy if hinge quality or installation precision is poor.

Block Board For Hinged Shutters

Block board performs well for wide or tall doors because its internal strip construction reduces warping. Many carpenters prefer it when shutters need to remain flat over long spans. Compared to engineered boards, it holds shape better under stress and stays aligned longer. That stability makes it a reliable cupboard material choice for shutters where structural balance matters more than surface detailing.

MDF For Shutters

MDF is widely used as a shutter base when finish quality is the priority. Its smooth surface makes it ideal for painted panels, routed patterns, or membrane finishes, which is why it's a common almirah material in decorative wardrobes. Structurally, it's weaker than plywood, so hinge installation must be precise. It works best for medium-size shutters rather than oversized doors that place constant stress on fittings.

Best Material For Sliding Wardrobe Doors

Sliding shutters behave differently from hinged ones, which means the best material for sliding wardrobe doors isn't always the strongest board but the one that balances weight, rigidity, and smooth movement. Panels that are too heavy strain rollers, while flexible boards can bow and affect alignment. Material choice here directly affects track life, noise levels, and long-term usability.

HDF For Sliding Panels

HDF is commonly used as a sliding wardrobe material because it offers a dense, uniform structure without excessive weight. That balance allows shutters to glide smoothly while still staying rigid across height. It also supports laminates and acrylic finishes well. However, edges must be sealed properly since moisture exposure can cause swelling that interferes with track movement. This material is very common in sliding wardrobe design.

MDF For Sliding Doors

MDF works well for sliding shutters when panel sizes are moderate and hardware quality is good. Its smooth surface makes it suitable for painted or membrane finishes, which is why it often appears in decorative sliding wardrobes. While it's not as strong as plywood, the horizontal load distribution of sliding systems reduces stress on the board, allowing MDF to perform reliably when the thickness is adequate.

Aluminium Frame Panels

Aluminium-framed shutters are often considered the most practical option for large sliding wardrobes. The metal frame carries structural load, while the panel insert can be glass, laminate board, or acrylic. This combination keeps shutters lightweight yet stable, reducing strain on tracks. For wide wardrobes or floor-to-ceiling units, aluminium systems are frequently chosen as the best material for wardrobe sliding formats.

Plywood For Sliding Doors

Plywood can be used for sliding shutters, but only when the hardware is strong enough to handle the weight. Thick plywood panels are heavier than engineered boards, which increases roller stress over time. In smaller wardrobes it performs well, though for large spans, it's rarely the first choice unless premium track systems are installed to support the load.

Plywood can be used for sliding shutters, but only when the hardware is strong enough to handle the weight. Thick plywood panels are heavier than engineered boards, which increases roller stress over time. In smaller wardrobes it performs well, though for large spans, it's rarely the first choice unless premium track systems are installed to support the load.

Termite-Proof Material For Wardrobe

No wardrobe material is naturally immune to termites, but some resist damage far better than others. The idea of a completely termite-proof material for wardrobe units is mostly a myth. What actually matters is board density, chemical treatment, and how well edges are sealed. Termites usually attack softer cores first, so material choice directly affects how vulnerable a wardrobe becomes over time.

Plywood With Treatment

Chemically treated plywood is one of the safer choices when termite resistance is a concern. Many manufacturers offer borate-treated or preservative-treated sheets that discourage infestation. Denser ply cores are harder for termites to penetrate, which makes them a practical best cupboard material option in regions where termite activity is common.

HDHMR And High-Density Boards

High-density engineered boards such as HDHMR resist termite damage better than low-density options because their compact structure leaves fewer internal gaps. Termites prefer porous material, so denser boards slow down the spread even if exposure happens. These boards are often used in premium or modern wardrobe materials systems where durability is prioritised.

Particle Board And Low-Density Boards

Low-density boards are the most vulnerable. Particle board, especially untreated versions, can be damaged quickly once termites reach the core. The loose internal structure allows them to travel and nest easily. This is why such boards are rarely recommended as the best material for wardrobe builds in termite-prone homes.

Best Material For Bedroom Wardrobe Based On Use Case

The best material for bedroom wardrobe units isn't decided by price or finish alone. It depends on how the wardrobe will actually be used. Storage load, lifespan expectations, and environment all influence which board performs best. A material that works perfectly in one home can fail quickly in another if usage patterns are different.

For Long-Term Homes

For wardrobes meant to last years, plywood remains the safest wardrobe material option. It handles daily wear, supports heavier storage, and keeps fittings secure over time. Homes located in humid regions especially benefit from moisture-resistant grades. When durability matters more than initial cost, plywood-based structures usually provide the most consistent long-term performance.

For Budget Or Short-Term Setups

If the wardrobe is intended for temporary use, particle board or MDF can work as a practical cupboard material choice. They reduce cost and still deliver a clean finished appearance. These boards suit rental homes or short-term interiors where lifespan expectations are lower and structural stress remains minimal.

For Kids' Or Light-Use Wardrobes

Wardrobes used mainly for lighter storage don't always require heavy structural boards. MDF or hybrid panels can perform well here because loads stay moderate. They also allow smoother finishes and rounded detailing, which is often preferred in bedroom interior decoration for children's rooms where safety and appearance matter as much as strength.

For Premium Or Custom Interiors

High-end wardrobes often combine materials rather than relying on one. Plywood may be used for structure, while shutters use MDF, glass, or acrylic panels. This mixed approach is common in designer interiors because it balances durability with aesthetics, especially when the wardrobe is part of a coordinated home interior ideas concept.

Modern Modular Wardrobe Materials Explained

Factory-made wardrobes use a different category of boards than traditional carpenter builds. These modern wardrobe materials are designed for machine cutting, uniform thickness, and predictable performance. Instead of relying only on raw strength, they focus on dimensional stability, smooth finishes, and fast installation.

Pre-Laminated Engineered Boards

Most modular wardrobes use pre-laminated particle board or MDF. These boards come factory-finished, so there's no polishing or laminating required on site. The uniform surface ensures consistent colour and texture across panels. While not the strongest structurally, they perform well in modular builds where panel sizes and loads are already calculated.

HDHMR Boards

High Density High Moisture Resistance boards are used in premium modular wardrobes. Their compact structure improves strength, reduces swelling risk, and supports hardware more securely than standard engineered boards. Because of this balance, they're often marketed as upgraded wardrobe material options for buyers who want factory precision with better durability.

Aluminium and Hybrid Panels

Some modular systems combine boards with aluminium frames for shutters or partitions. The frame carries structural stress, while the insert panel provides finish and style. This combination keeps panels lighter yet stable, which helps maintain alignment over time. Hybrid systems are common in large wardrobes or layouts integrated into walk-in closet design concepts.

Factory vs Carpenter-Made Materials

Factory wardrobes prioritise consistency, while carpenter-made wardrobes prioritise flexibility. Modular boards are cut with precision machines, which reduces size variation. Carpenter builds allow material selection freedom, such as choosing thicker plywood or block board. The better choice depends on whether accuracy or customisation matters more for the project.

Best Material For Walk-In Closet Design

Open storage changes how materials behave. In a walk-in closet design, boards stay exposed to air, dust, and constant handling, so the best material for walk-in closet systems must balance strength with surface durability. Unlike closed wardrobes, there's no shutter protection, which means edges, finishes, and board stability all matter more than usual.

Plywood For Structural Sections

Plywood works well for frames, vertical panels, and long shelves because it handles weight without bending and keeps fittings secure. In larger closet layouts where sections span wall to wall, its stability helps maintain alignment over time. That reliability makes it one of the most practical wardrobe material options for structural parts of open closets.

Engineered Boards For Visible Panels

For exposed shelving and partitions, engineered boards like MDF or HDF are often used because they provide smoother surfaces and consistent finishes. They allow cleaner laminates and painted coatings, which help maintain visual uniformity across open storage. When loads remain moderate, these boards perform well as modern wardrobe materials in visible areas.

Glass and Acrylic Elements

Some walk-in layouts include glass or acrylic shelves for a lighter appearance. These materials don't serve as primary structure but work as accent surfaces supported by metal brackets or frames. They're usually added selectively to enhance visibility and style rather than replace core materials for wardrobe cabinet construction.

Wardrobe Material Options by Budget Range

Cost influences material choice more than most people expect. The right wardrobe material options aren't about picking the cheapest or the most expensive board, but about matching material strength to how the wardrobe will actually be used. Budget mainly affects density, durability, and finish quality, so understanding what each price level offers helps avoid overpaying or underbuilding.

Low Budget Range

At the entry level, particle board and basic MDF are the most common choices. These boards keep costs down and still allow decent finishes, which is why they appear often in affordable wardrobes. They work best for lighter storage and shorter expected lifespans. In this range, selecting the right thickness matters more than chasing premium labels among cupboard making materials.

Mid-Range Budget

Mid-range wardrobes usually combine plywood for structure with MDF or engineered panels for shutters. This mix balances strength with appearance, making it one of the most practical materials for wardrobe combinations. It supports heavier storage while still allowing decorative finishes, which is why many long-term residential wardrobes fall into this category.

Premium Budget

Higher budgets allow denser boards, treated plywood, HDHMR panels, or hybrid aluminium systems. These materials offer better moisture resistance, stronger screw holding, and longer lifespan. Premium wardrobes often use a mix of boards rather than one type, selecting each based on function. This layered approach is common in high-end interiors where durability and finish quality both matter.

Wardrobe Material Specification Checklist Before Buying

Material names alone don't guarantee quality. Two wardrobes can both claim the same wardrobe material specification, yet perform very differently after installation. What actually determines durability is a combination of thickness, density, finishing, and hardware compatibility. Checking a few technical details before finalising materials helps avoid structural issues that only show up after months of use.

Board Thickness

Thickness directly affects strength. For most wardrobes, 18 mm is considered a safe standard for carcass and shelves, while thinner boards are usually limited to backing or partitions. Even strong wardrobe raw materials can fail if the thickness is insufficient for the span they need to cover.

Core Density and Composition

The internal core decides screw grip and load tolerance. Dense boards hold fittings better and resist wear longer. Low-density boards may look identical from the outside, but loosen around hinges and shelf supports. Always confirm the density grade when comparing materials for wardrobe cabinet builds.

Edge Sealing and Banding

Edges are the most vulnerable part of any board. Proper sealing prevents moisture entry, swelling, and gradual damage. Good edge banding also improves durability at corners where daily handling causes friction. In humid conditions, edge finishing matters as much as the baseboard itself.

Surface Finish Compatibility

Not every board supports every finish. Some laminates adhere better to plywood, while painted finishes bond more smoothly to MDF. Matching finish type with board type ensures both durability and appearance remain consistent, especially in wardrobes designed as part of a coordinated interior.

Hardware Support Strength

Hinges, channels, and handles all depend on the board's ability to hold screws firmly. Weak cores loosen over time, which leads to misaligned shutters or unstable shelves. Checking screw-holding capacity is one of the simplest ways to judge whether a board qualifies as the best material for making wardrobes.

Common Mistakes When Choosing Cupboard Design Materials

Choosing the wrong board rarely looks like a mistake at first. Problems show up later when shelves begin to bend, hinges loosen, or panels react to moisture. Most of these issues don't come from installation errors but from poor material decisions made early while selecting cupboard design materials.

- Choosing the finish before the core cupboard material

- Picking low-density boards for heavy storage.

- Ignoring room humidity when selecting wardrobe material options.

- Using the same board for structure, shelves, and shutters.

- Selecting thin panels instead of proper thickness.

- Trusting brand names without checking specifications.

- Skipping edge banding quality checks.

- Choosing heavy boards for sliding wardrobe design

- Ignoring the screw holding capacity of the board.

- Selecting materials based only on price, not lifespan.

- Not confirming termite resistance treatment.

- Fixing wardrobes directly against damp walls.

The Right Wardrobe Material

A wardrobe may look perfect outside, but its performance depends on the materials inside. The internal board decides whether shelves stay straight, shutters align, and fittings remain secure with daily use. Different boards serve different roles, so the best results come from matching material to function rather than choosing one option for everything. Many homeowners planning wardrobes through Interior Company focus on these structural details early. This leads to their storage being stable and attractive for years.

*Images used are for representational purposes only. Unless explicitly mentioned, the Interior Company does not hold any copyright to the images.*

Wardrobe Design Ideas for You

- Type

- Color

- Finish

- Theme

- Size

- Gender

- Floor Material

- Orange Color Wardrobe Design

- Gold Color Wardrobe Design

- Green Color Wardrobe Design

- Grey Color Wardrobe Design

- Light Brown Color Wardrobe Design

- Multi-Coloured Color Wardrobe Design

- Natural Brown Color Wardrobe Design

- Black Color Wardrobe Design

- Pink Color Wardrobe Design

- Red Color Wardrobe Design

- Silver Color Wardrobe Design

- White Color Wardrobe Design

- Yellow Color Wardrobe Design

- Cream Color Wardrobe Design

- Beige Color Wardrobe Design

- Blue Color Wardrobe Design

- Brown Color Wardrobe Design

- Cashmere Color Wardrobe Design

- Dark Brown Color Wardrobe Design

- Painted Wood Floor Material Wardrobe Design

- Concrete Floor Material Wardrobe Design

- Plywood Floor Material Wardrobe Design

- Porcelain Tile Floor Material Wardrobe Design

- Ceramic Tile Floor Material Wardrobe Design

- Medium Hardwood Floor Material Wardrobe Design

- Dark Hardwood Floor Material Wardrobe Design

- Slate Floor Material Wardrobe Design

- Carpet Floor Material Wardrobe Design

- Marble Floor Material Wardrobe Design

- Vinyl Floor Material Wardrobe Design

- Light Hardwood Floor Material Wardrobe Design

- Laminate Floor Material Wardrobe Design

Ready for a home transformation?

Let our designers assist you!

Recent Posts

If durability is the priority, plywood usually lasts the longest. It holds screws firmly, handles weight without bending, and stays stable even when humidity changes. Other boards can work too, but for long-term daily use, plywood tends to outperform most options because its layered structure resists stress better.

MDF isn’t bad. It just isn’t meant for every part of a wardrobe. It works well for shutters or decorative panels where finish matters, but for shelves or the main structure, stronger boards perform better. Used in the right place, MDF does its job. Used everywhere, it may not hold up as well over time.

No board is completely termite-proof, but denser materials slow damage significantly. Treated plywood or high-density engineered boards resist infestation better than low-density ones. Proper sealing, installation height, and wall treatment matter just as much as board choice because termites usually enter from surrounding surfaces, not the board itself.

Most shelves bend because of either thin boards or weak core material. Long spans with heavy clothing stacks put constant pressure on the centre of the shelf. If the board lacks stiffness or thickness, it slowly dips. Stronger material or proper thickness usually prevents this problem before it starts.

Surface appearance can be misleading because laminates make different boards look identical. The real difference is inside. Check thickness, density, weight, and screw grip instead of judging by finish. Asking for board specifications or grade details usually reveals more about quality than visual inspection ever can.

Related Category

- Balcony

- Bedroom

- Kids Room

- Kitchen

- Living Room